Our partners:

|

|

Our company has the European Technical Assessment (ETA)!

All of the components are 1st class and approved with relevant certificates.

Purpose of the house:

- family homes

- holiday homes

- garden sheds

- tool sheds

Appearance of the house:

-Thin (4.2cm) planed post and beam houses

Amongst our services the thin post and beam houses provides the cheapest option. The planed beam is an excellent choice for wall structures of holiday houses on their own but the timber enclosed with insulation in these houses shows excellent thermal properties. The thin post and beam houses can be family homes as well as holiday homes.

-Thick (9.5cm or 11.5cm) planed post and beam houses

The thick post and beam houses are in the highest price category. This type is the perfect choice for family homes. Its features are similar to the thin straight post and beam houses even though the thick beam gives a certain hefty feel to it, not to mention the more valuable insulation attributes. The thick planed beam houses too can become family as well as holiday homes.

-Lightweight timber frame houses

This category means the option for a family home with a low price tag. These houses are based on timber frames with extreme strength. With the applied external and internal insulation systems these houses possesses excellent thermal efficiency.

The most often quoted houses are the post and beam as well as the lightweight timber frame (sandwich-panel-frame) houses. The outer layer of the post and beam houses is a rustic, planed, double grooved, so called "harrow" beam wall. Whereas the "lightweight" constructions exteriors resemble conventional houses since the outer foam board insulation receives 0.15-0.2 cm plastering. In both cases we insulate with rock wool slabs in the framework and line the interior walls with either v-groove panels or plasterboards. These structures render seven times better thermal insulation properties than plastered brick walls and twice as much as the post and beam houses built in the northern countries*.

The wooden frame-work

In the modern timber frame construction there is a brand new innovation i.e. the solid structural timber. In the past years more and more architects and carpenters criticized the disadvantages of conventional timber (cracking, shrinkage, distortion, etc.). In the modern timber frame construction there is a brand new innovation i.e. the solid structural timber. In the past years more and more architects and carpenters criticized the disadvantages of conventional timber (cracking, shrinkage, distortion, etc.).

The modern timber construction continually improves. For the architects, carpenters, and timber frame constructors, the solid structural timber is widely available as well as being a brand new dimension with its multi purpose and "green" nature.

|

Outstanding and efficient constructional timber protection by artificial (kiln) drying

By the artificial drying of the KVH solid structural timber the moisture content of the wood can decrease up to 15% in which case one can rule out any risks that might happen when the timber dries out following the installation - cracking, deformation, mildewing, aesthetic imperfections. The artificial drying process is required in order to eliminate the use of chemical wood preservers. Therefore the artificial drying is the most efficient way to preserve wood.

Because of this the solid structural timber becomes an exceptional construction material. During the few-days drying the temperature can reach up to 70C in the middle of the timber's diameter for many hours so therefore the components of the wood such as protein which provides nutrition for the insects alters in a way that the risk caused by the wood boring insects is minimised in the KVH timber.

The wall structure built of KVH delivers much more in terms of quality than conventional pine.

|

KVH (Konstruktionsvollholz) - constant quality structural timber

The KVH is made of shorter sections with finger joints carved into the ends and glued together after the elimination of the any knots. By this technology a long and flawless product is manufactured which in terms of solidity reaches the standard of conventional timber. The KVH is made of shorter sections with finger joints carved into the ends and glued together after the elimination of the any knots. By this technology a long and flawless product is manufactured which in terms of solidity reaches the standard of conventional timber.

The solid structural timber is made of timber tested and qualified for stiffness then the product comes with the relevant classification. The KVH traded in Hungary is manufactured mainly in Austria.

As the KVH's final use is not known at the manufacturing process, it is glued with high solidity water-resistant (usually resorcinol) glue. The KVH is labelled in all cases with qualifications of the Austrian standards (Srotierklasse), too.

The KVH is obviously more expensive than conventional timber however the length, the flawless, guaranteed finish makes it all competitive.

|

The stonewool insulation (28 kg/m3)

The stone-wool is thermosetting, mainly made of volcanic or sedimentary rock. The stone-wool type of insulation does not shrink has no thermal movements and their thermal insulating attributes last up to the building's lifetime. They do not need any maintenance and they function as acoustic insulation as well. It is exceptionally fire-proof, its melting-point breaches the 1000C. This thermal insulating material's excellent quality guarantees to maintain the building's internal temperature, as well as the structure won't act as thermal bridge as opposed to the low density pads or blankets in which case the consequence is the decreasing quality due to the shrinkage of the building's enclosure and the thermal bridging. The stone-wool is thermosetting, mainly made of volcanic or sedimentary rock. The stone-wool type of insulation does not shrink has no thermal movements and their thermal insulating attributes last up to the building's lifetime. They do not need any maintenance and they function as acoustic insulation as well. It is exceptionally fire-proof, its melting-point breaches the 1000C. This thermal insulating material's excellent quality guarantees to maintain the building's internal temperature, as well as the structure won't act as thermal bridge as opposed to the low density pads or blankets in which case the consequence is the decreasing quality due to the shrinkage of the building's enclosure and the thermal bridging.

|

|

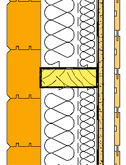

Post and beam house - frontage:

fire-proof plasterboard,

2 cm stave frame / air gap,

moisture control polyethylene foil,

5 cm horizontal stave frame in between mineral wool layer,

10 cm vertical pine frame panels, in between mineral wool layer,

9 cm double tongue and groove joined, planed pine beams, horizontally laid on top of each other.

Thermal conductivity: 0,24 W/m2K

|

|

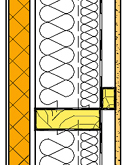

Lightweight timber frame house - frontage:

fire-proof plasterboard,

2 cm stave frame / air gap,

moisture control polyethylene foil,

15 cm vertical pine frame panels, in between mineral wool layer,

1.2 cm OSB board, 5 cm polistirol foam plate, 0.2 cm plastering.

Thermal conductivity: 0,216 W/m2K

|

|

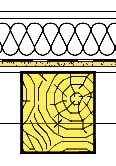

Partition wall structure:

fire-proof plasterboard,

2 cm stave frame / air gap,

moisture control polyethylene foil,

10 cm vertical pine frame panels, in between mineral wool layer,

moisture control polyethylene foil,

2 cm stave frame / air gap,

fire-proof plasterboard,

Acoustic insulation performance: R'W=min 40 dB

|

|

Visible beam ceiling (ground floor):

2 cm planed, plank flooring

5/10 cm joists in between 15 cm thermal insulating

moisture control polyethylene foil,

1.25 cm fire-proof plasterboard

1.6 cm pine v-groove panels

15/15 cm visible pine beam

Thermal conductivity: 0,216 W/m2K

|

|

Plank ceiling (ground floor):

2 cm spaced planking

5/20 cm plank structure, in between 15 cm thermal insulation

moisture control polyethylene foil,

2 cm levelling stave framework

1.25 cm fire-proof plasterboard

Thermal conductivity: 0,216 W/m2K

|

*28 cm pine post and beam house thermal conductivity: 0.44-0.48 W/m2K

*25 cm plastered brick wall thermal conductivity: 1.42 W/m2K

* In calculation we considered the external and internal thermal resistances, too.

|